< Previous | Contents | Next >

Annex 2-7 Guidance for non-destructive testing of ship hull steel welds

1. General

(1) Application

(A) This Guidance applies to the Non-destructive inspection for all hull welds of ships whose, in general, length exceeds 30 m to confirm the quality of the hull welds. Effective date of this Guidance is the date of contract for construction.

(B) In ships of less than 30m in length, the range of the inspection, the members to be in- spected and the number of checkpoints are to be determined by the Surveyor based on con- sultation with the manufacturer.

(C) The quality levels given in this Guidance refer to production quality and not to fitness for-purpose of the welds examined.

(D) The non-destructive testing is normally to be performed by the Shipbuilder or its subcon-

tractors in accordance with this Guidance. Surveyor may require to witness some testing.

(E) It should be the Shipbuilder's responsibility to assure that

dures are adhered to during the construction and the report on the findings made by the NDT.

(F) This Guidance is intented to apply to welds of irons and

testing specifications and proce- is made available to the Society

nonferrous metals. Other marine

structures may be applied subject to the approval by the Society. However, in case of ultra-

sonic inspection, the transducer design and calibration block material used are appropriate to

the material under inspection.

(2) Means of Non-destructive Inspection

(A) Applicable methods for testing of the different types of weld joints are given in Table 1.

![]()

![]()

Table 1 Applicable methods for testing of weld joints

Weld Joint | Parent material thickness(mm) | Applicable testing methods |

Butt welds with full penetration | t 8 | VT, PT, MT, RT |

t > 8 | VT, PT, MT, UT, RT | |

Tee joints, corner joints and cruciform joints with full penetration | t 10 | VT, PT, MT |

t > 10 | VT, PT, MT, UT | |

Tee joints, corner joints and cruciform joints without full penetration and fillet welds | All | VT, PT, MT, UT(1) |

Note: (1) UT can be used to monitor the extent of penetration in tee, corner and cruciform joints. | ||

(B) All welds should be subject to visual testing by personnel designated by the Shipyard.

(C) Non-destructive inspection for detection of surface imperfections of weld joints of hull con- struction is, in principle, to be magnetic particle testing specified in 2 (2) However liquid penetrant testing can be applied under consideration of this Society.

(D) Non-destructive inspection for detection of internal imperfections is, in principle, to be radio- graphic inspection specified in 3. However, for larger thickness over 30 mm, ultrasonic in- spection specified in 4 is to be used as the primary inspection method.

(E) For welded joints of hull construction in thickness of 8 mm and above, a part or all of ra- diographic inspection may be replaced by the ultrasonic inspection based on the requirements given in 4, in case that the shipyard submitting ultrasonic testing specifications containing information on the items mentioned below

(a) Approval of inspection manual

Prior to carrying out the inspection, the shipyard has to submit the inspection manual containing the items mentioned below, and have the manual approved by the Society.

(i) Type of ultrasonic detector and kind of probe (nominal frequency and material, di-

mension, type and nominal angle of refraction of transducer), and

range of the testing (thickness, welding process, etc.)

(ii) Calibration block and reference block for calibration

(iii)Kind of ultrasonic test process (Angle beam technique is to be of

the applicable

standard one),

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 81

![]()

and extent of the measurements and method for sensitivity adjustment for the proc- ess

(iv)Judgement criteria for ultrasonic test (The criteria for angle beam technique test is

to be in accordance with Table 11. For the other kind of ultrasonic test process, judgement criteria are to be described in detail.)

(v) Record of the results of ultrasonic test

(vi)List of operators and judges

(b) The capability of shipyard

The capability of shipyard about the reliability of the test methods is to judged by the

items mentioned below.

(i) Qualification of engineers

(ii) Quality control conditions

(iii)Reliability

(iv)Keeping the Standards and their application ability

(v) Documents for type, extent and repair of defects

(c) Confirmation by radiographic inspection

(i) When the initial ultrasonic inspection is carried out according to this Guidance, ul- trasonic testing for 1/10 of welds to be subject, based on the instructions of the

Surveyor, to radiographic testing of at least three ships to confirm that the results match those of (a) (iv) and is approved by the Society for the consistence. However

the confirmation by radiographic inspection can be waived for the shipyard which

has the records to carry out confirmation inspection more than 3 ships.

(F) Where a yard desires to use ultrasonic inspection as the primary inspection method accord- ing to (E), following requirements to be complied.

(a) a reasonable amount of checkpoints are to be examined by the radiography or alter- native means approved by the Society. The amount examined together with the area

covered are to be agreed and marked on the NDE plan specified in (5).

(b) Radiographic inspection may be required at random in important locations at the dis- cretion of the Surveyor.

(G) Alternative means to the radiographic inspection

(a) In case where shipyard intend to apply the new advanced NDT technologies such as Phased array UT (PAUT) or Time of Flight Diffraction (TOFD) in lieu of radiographic inspection, the shipyard has to submit the inspection manual as specified above (E), (a)

and have the manual approved by the Society.

(b) Additional test and/or data for comparison of alternative means with radiographic in- spection may be required when deemed necessary by the Society.

(H) The additional non-destructive inspection required for workmanship control of welded joints of hull is to be in accordance with the requirements specified in 3 (2), (C).

(3) Testing apparatus

The testing apparatus of radiographic and ultrasonic Inspection are to be calibrated and/or cor- rected in accordance with the recognised national or international standards.

(4) Personnel requirements

(a) Personnel carrying out non-destructive inspection are generally to be qualified and certified to Level II or above in K S B ISO 9712, SN T -T C -1A , E N 473, ASNT Central Certification Program (ACCP) or equivalent. However, the personnel qualified to Level I can engage in the testing under supervision of those qualified for Level II 2 or above.

(b)

(c)

Personnel responsible for the radiographic and/or ultrasonic Inspection activity including ap- proval of procedures should be qualified and certified to Level III.

Periodic re-evaluations of test personnel are to be conducted in accordance with K S B ISO

9712 or equivalent to verify that such capability is maintained.

(5) NDE plan

(a) The Shipbuilder should submit a plan for approval by the Society, specifying the areas to be examined and the extent of testing with reference to the NDT procedures to be used ac- cording to the ship design, ship type and welding processes used. Particular attention should

be paid to highly stressed areas.

(b) The plan should supervision.

only be released to the personnel in charge of the NDT and its

(c)

The identification

examined.

system should identify the exact locations of the lengths of weld

![]()

82 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

(d) Welded connections of large cast or forged components (stern frame, stern boss, rudder

parts, shaft brackets...) should be tested over their agreed locations using RT or UT.

(e) All start/stop points in welds made using automatic be examined using RT or UT except for internal

should be agreed.

(6) Timing of NDT

(a) NDT should be conducted after welds have cooled

weld heat treatment where applicable.

full length using MT or PT and at

(mechanised) welding processes should members where the extent of testing

to ambient temperature and after post

(b) For steels with specified minimum yield stress of 420 N/mm2 and above, NDT should not be carried out before 48 hours after completion of welding. Where post weld heat treatment

(PWHT) is carried out or consistent low failure rate of delayed cracking has been docu- mented for the materials and welding consumables in question, the requirement for testing after 48 hours may upon agreement be reduced.

(7) Performance and responsibility

(a) The non-destructive testing is normally to be performed by the Shipbuilder or its subcon- tractors in accordance with inspection manual and NDE plan approved by the Society. The Surveyor may require to witness some testing.

(b) It should be the Shipbuilder's responsibility to assure that testing specifications and proce- dures are adhered to during the construction and the report is made available to the Society on the findings made by the NDT.

(8) Surface inspections

(a)

(b)

(c)

Surface inspections shall be carried out as bellows;

The surface of welds to be radiographed are to be sufficiently free from irregularities that may mask or interfere with interpretation

The test surface (within I skip distance from welds edge) to be ultrasonic tested are free from spatter, floating scales, painting film, remarkable rust which prevent transmission of ul-

trasonic wave and the likes. They are removed if existed.

2. NDT for detection of surface imperfections

(1) Visual testing

(a) The welds examined should be clean and free from paint.

(b) Acceptance criteria are given in Table 2.

![]()

Table 2 Acceptance criteria for visual testing, magnetic particle and liquid penetrant testing

Surface discontinuity | Acceptance criteria for visual testing |

Crack | not accepted |

Lack of fusion | not accepted |

Incomplete root penetration in butt joints welded from one side | not accepted |

Surface pore | Single pore diameter d 2.5d as minimum distance to adjacent pore. |

Undercut in butt welds | depth 0.5mm whatever is the length depth 0.8mm with a maximum continuous(2) length of 90mm |

Undercut in fillet welds | depth 0.8mm whatever is the length |

Note: (1) “t” is the plate thickness of the thinnest plate and “a” is the throat of the fillet weld. (2) Adjacent undercuts separated by a distance shorter than the shortest undercut should be regarded as a single continuous undercut. | |

![]()

(2) Magnetic particle testing

(a) Methods of inspection not specified in this Guidance are to comply with the K S B ISO

9934-1 or other recognized standard subject to the approval by the Society.

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 83

![]()

(b) The Shipbuilder should submit a procedure for approval by the Surveyor, specifying the sur-

(c)

(d)

face preparation, magnetizing equipment, calibration methods, detection tion, viewing conditions and post demagnetization.

The surface to be examined should be free from scale, weld spatter, paint and should be clean and dry.

When using current flow equipment with prods, care shall be taken to

media and applica-

oil, grease, dirt or avoid local damage

(e)

to the material. Copper prod tips must not be used. The prod tips should be lead, steel, aluminium or aluminium-copper braid.

To ensure detection of discontinuities of any orientation, the welds are magnetized in two

directions approximately perpendicular to each other with a maximum deviation of 30°. Adequate overlapping shall ensure testing of the whole zone.

(3)

(f) Continuous wet particle method should be used as far as practicable.

(g) magnetic particle testing should cover a minimum weld length of 500 mm.

(h) Acceptance criteria are given in Table 2. Only the indications which have any dimension greater than 2 mm should require evaluation.

Liquid penetrant testing

(a) Methods of inspection not specified in this Guidance are to comply with the K S B ISO

3452 or other recognized standard subject to the approval by the Society.

(b)

The Shipbuilder should submit a procedure for approval by the Surveyor, specifying the cal- ibration equipment, surface preparation, cleaning and drying prior to testing, temperature range, type of penetrant, cleaner and developer used, penetrant application and removal, pen-

(c)

etration time, developer application and development testing.

The surface to be examined should be clean and free

and should include the weld bead and base metal for

time and lighting conditions during

from scale, oil, grease, dirt or paint at least 10 mm on each side of the

(d)

(e)

weld, or the width of the heat affected zone, whichever is greater.

The temperature of parts examined should be typically between 5°C and 50°C, outside this

temperature range special low/high temperature penetrant and reference comparator blocks should be used.

![]()

The penetration time should not be less than 10 minutes and in accordance with the manu-

fcaocrtduarnecr’es wspitehciftihceatimona.nuTfhacetudreevr’eslosppmeecniftictaitmioen,shnoourlmdalnloyt bbeetwleesn t1h0an 3100 mmininuutetess.

(f) magnetic particle testing should cover a minimum weld length of 500 mm.

and in ac-

(4)

(g) Acceptance criteria are given in Table 2. Only the indications which have any dimension greater than 2 mm should require evaluation.

Survey records

(A) In addition to generic items, reports of magnetic particle testing should include the following specific items and their records are to be filed to compare the inspection locations with

their results.

(a) type of magnetization

(b) magnetic field strength

(c) detection media

(d) viewing conditions

(e) demagnetization, if required

(B) In addition to generic items, reports of liquid penetrant testing should include the following

specific items and their records are to be filed to compare the inspection locations with their results.

(a) type of penetrant, cleaner and developer used

(b) penetration time and development time

3. Radiographic Inspection

(1) Methods of radiography

(A) Methods of inspection not specified in this Guidance are to comply with the K S B

0845(Methods of radiographic examination for welded joints in steel) or other recognized standard subject to the approval by the Society.

(B) Test range of radiographic inspection is to be not less than 250 mm or overall length of the

welds inspected, whichever is smaller.

(C) Processed films should display hull no., frame no., weld boundary indicators, Port/Starboard, location (or film serial number) and date as radiographic image.

![]()

84 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

(D) Film density

Film density through the area of interest shall be within 1.8 to 4.0 except for the defect images.

(E) Penetrameter

(a) The penetrameter is to be a wire type image quality indicator specified in the K S B ISO

19232, ISO 1027 or equivalent.

(b) The penetrameters including wire having minimum perceptible diameter are to be placed across a weld and near the both edge (end) of the weld, facing the radiation source.

However, if the length under examination is less than three times the width of pene- trameter, only one penetrameter may be laid on the center of the weld length.

(c)

(d)

Minimum perceptible wire diameter of penetrameter on the radiographic films are to be less than the value specified in Table 3.

When using IQI's of wire type, the image of a wire is considered visible on the film if a continuous length of at least 10 mm is clearly visible in a section of uniform optical

density.

Table 3 Minimum perceptible wire diameter of penetrameter (Unit : mm)

Thickness of base metal | Minimum perceptible wire diameter of penetrameter (mm) | Thickness of base metal | Minimum perceptible wire diameter of penetrameter (mm) |

t 4.0 | 0.10 | 32.0 < t 40.0 | 0.63 |

4.0 < t 6.3 | 0.16 | 40.0 < t 63.0 | 0.80 |

6.3 < t 10.0 | 0.20 | 63.0 < t 80.0 | 1.00 |

10.0 < t 12.5 | 0.25 | 80.0 < t 125 | 1.25 |

12.5 < t 16.0 | 0.32 | 125 < t 200 | 1.60 |

16.0 < t 20.0 | 0.40 | 200 < t 320 | 2.00 |

20.0 < t 32.0 | 0.50 | 320 < t | 2.50 |

![]()

![]()

(2) Extent of survey

(A) Survey of welded joints of the shell and deck plating in ships

(a) The number of checkpoints

The minimum number of radiographic check points for the welded joints

and deck plating in ships is to be governed by the following equation or

the length of the ship(m), (round off), whichever is the greater.

of the shell the same as

![]()

![]()

(b)

![]()

= minimum number of checkpoints

= length specified in Pt 3, Ch 1, 102. of the Rules (m)

= breadth specified in Pt 3, Ch 1, 104. of the Rules (m)

= depth specified in Pt 3, Ch 1, 106. of the Rules (m)

Survey location and distribution of checkpoints

(i) Survey location and distribution of checkpoints are to comply with the in Table 4. These inspection spots are not to adjoin each other.

requirements

(ii) In the distribution of checkpoints, the selection of inspection locations is to be con-

![]()

sidered the followings and carried out by the field Surveyor.

Welds in high stressed areas

Welds which are inaccessible or very difficult to inspection in service

Intersections of field erected welds

(iii)If the welds to be inspected can not be inspected because of the

structure, other

possible welds in the vicinity of that weld are to be subjected to radiographic inspection.

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 85

![]()

![]()

Table 4 Survey location and distribution of checkpoints for the welded joints of the shell and deck plating in ships

Survey location | distribution of checkpoints | |

Butt welds within 0.6 L midship | Butt welds outside 0.6 L midship | |

(1) Strength deck(excluding the area within hatch side lines) (2) Sheer strake, (3) Side shell plating, (4) bilge strake (5) Bottom shell plating, (including flat plate keel.) (6) Hatch side coaming(including the top plate)(1) | (2) |

|

Note (1) Butt joints of the hatch side coaming exceeding 0.15L in length. (2) one-third of the number of checkpoints is to be the intersections of weld lines. | ||

(B) Survey of welded joints of internal structural members of ships

(a) Survey location and distribution of checkpoints are to comply with Table 5. These in- spection spots are not to adjoin each other.

(b) Distribution of checkpoints is to be as specified in (2), (A), (b), (ii)

Table 5 Survey location and

members of ships

distribution of checkpoints for the welded joints of internal structural

Survey location | distribution of checkpoints(1)(2) | |

within 0.6L midship | outside 0.6L midship | |

Butt welds | ||

(1) Web and face plates of longitudinal members on the strength deck (deck longitudinal, girders under deck and above deck).(longitudinal on the deck within the side lines of a cargo hatch opening are excluded.) |

|

|

(2) Uppermost steel plate of longitudinal bulkheads. |

| |

(3) Lowermost plate of the longitudinal bulkhead. |

| |

(4) Web and face plates of longitudinal members (longitudinal frames, centerline girder plate, etc.) on sheer strake, shell plating, turn of bilge strake and keel plate. |

| |

(5) Web and face plates of transverse and horizontal girders. |

| |

Note (1) Number of inspections is to round up decimal places per joints of each members subject to inspections. (2) Distribution of number of inspections may change in consideration of the type of ship, structural arrang ement, welding process, arrangement of joints, etc. | ||

(C) Workmanship control of welded joints of hull

(a) In addition to preceding (A) and (B), non-destructive testing may be required addition- ally for parts of start, interrupted and end points of automatic welded joints, welded joints of hatch corner, connections of stern frame or rudder horn made of casting steel to rolled steels for hull, welded joints of insert plate for working holes and welded joints in the vicinity of parts where stress is concentrated.

![]()

86 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

(b) In addition to (a) above, non-destructive testing may be required additionally for the

areas where welding workmanship is suspect, the areas where

have been adopted, the areas where defects are liable to occur are inaccessible or very difficult to inspect in service and

new welding methods

easily, the welds which other appropriate areas

deemed necessary by the Surveyor to encourage good welding work.

(c) The locations of and the number of joints to be inspected additionally according to (a)

and (b) above are to be appropriately decided by the Surveyor according to the actual status of workmanship of the shipyard.

(D) Addition/Reduction in the number of checkpoints

(a) If it is deemed necessary in considering the results of visual inspection for welds of the members, the Surveyor may require, additional non-destructive inspections for welds oth- er than those subject to non-destructive inspection, or alteration of non-destructive in- spection procedure.

(b) If the survey results (before repair) of a previously constructed ship show that the num- ber of welds that need to be repaired exceeds 20 % of the total number of locations, then the number of checkpoints is to be a minimum of twice the number required.

(c)

If automatic welding has been carried out at joints to be surveyed and the results of the survey verify that the quality of the welding procedure is consistent satisfactory quality, the number of checkpoints may appropriately be reduced.

(d) If a weld that needs to be repaired is found from automatically welded joints whose number has been reduced in accordance with (c), additional radiographs amounting to the number of checkpoints as prescribed in (c), are to be taken immediately. The num-

ber of checkpoints is not to be reduced until an appropriate period has elapsed and the quality is verified to be stable and satisfactory.

(e)

For ships whose length 120 m or under, the survey locations and the number of check- points can be reduced.

(3) Acceptable Criteria of Radiographic Inspections

In radiographic testing, the Surveyor is to decide whether or not the results are acceptable when the test records specified in 3. (5) The judgement may be required to the engineers of the ship-

builder (personnel with qualifications) but the results of its judgement frequently are to be

verified. Where deemed necessary by the society, all radiographic films related with the ship are

to be submitted.

(A) Classification of Defects

(a) Classification of defects is to be as given in Table 6.

Table 6 Classification of defects

Types of defects | Kind of defects |

Type 1 | Porosity(blow hole) and similar defects |

Type 2 | Elongated slag inclusion, pipe, incomplete penetration, incomplete fu- sion, and similar defects |

Type 3 | Crack and similar defects |

(b) Where it is difficult to classify the defects into type 1 or type 2, classify respective de- fects into type 1 or type 2, and then decide whether or not the results are acceptable.

(c) In case of butt welded joints between plates with different thickness, thickness of the thinner plate is taken.

(B) Defect of Type 1

(a) Size of defect of type 1 is to be represented by score defect. The test field vision specified in Table 8 is to be that the defects of maximum size exists and the sum of

and maximum length of the selected from radiographic so size of defects is maximum.

Where the flaw falls on the boundary of the test field of vision, the part outside the test field of vision shall be included for measurement.

(b) The score of defect in the case of single defect of type 1 shall be determined by using

the value in Table 7 according to the dimension of the major diameter of the The score of defect for two or more defect of type 1 shall be the grand total

score for each defect in the test field of vision.

defect. of the

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 87

![]()

Major diameter of flaw (mm) | Up to and incl. 1.0 | Over 1.0, up to and incl. 2.0 | Over 2.0, up to and incl. 3.0 | Over 3.0, up to and incl. 4.0 | Over 4.0, up to and incl. 6.0 | Over 6.0, up to and incl. 8.0 | Over 8.0 |

Score | 1 | 2 | 3 | 6 | 10 | 15 | 25 |

Table 7 Score of defect Units : mm

(c) The defects of type 1 are to be judged unacceptable, the value of acceptable criteria specified in Table 8.

if the size of the defects exceeds

![]()

![]()

![]()

![]()

Table 8 Acceptance criteria for type 1 defect

Thickness of base metal t(mm) | t | 10 | 10 < t | 25 | 25 < t | 50 | 50 < t | 100 | |

Test field of vision | 10 mm × 10 mm | 10 mm × 20 mm | |||||||

Acceptance criteria | Maximum size of single defect (mm) | 4 | 5 | t/5 | 10 | ||||

Total score of defect | 6 | 12 | 24 | 30 | |||||

Note (1) Where the thickness of base metal is not more than 25 mm, the defects of not more than 0.5 mm may be ignored. Where the thickness of base metal is more than 25 mm, the defects of n ot more than 0.7 mm may be ignored. | |||||||||

(C) Defect of Type 2

(a) Size of defect of type 2 is to be represented by length of the defect. Where defects are

present in a row and the distance between the mutual defects does not exceed the length of larger defect, the sizes of all defects including the spaces between the mutual

defects is to be considered as the length of the defect.

(b)

(c)

The defects of type 2 are to be judged unacceptable, if the length of a defect exceeds the value of acceptable criteria specified in Table 9.

Incomplete root penetration is not accepted in butt joint welded from one side

![]()

![]()

Table 9 Acceptance criteria for type 2 defect

Thickness of base metal t (mm) | t 12 | 12 < t 50 | 50 < t | |

Acceptance criteria | Sum of size of defect (mm) | 6 or under | t/2 or under | 24 or under |

(D) Defect of Type 3

Any defect of type 3 is to be judged unacceptable.

(E) In Case of Coexistence of Defects of Type 1 and Type 2

Where two or more types of defects are coexistent, the defects are to be judged un- acceptable, provided the size of defects of each type are more than half of the size speci- fied in Table 8 and Table 9 respectively.

(4) Repair and Treatment after the Repair

(A) Unacceptable indications should be eliminated and repaired where necessary. The repair welds should be examined on their full length using ultrasonic or radiographic testing

method.

(B) When unacceptable indications are found, additional areas of the same weld length should be examined unless the indication is judged isolated without any doubt. In case of automatic

welded joints, additional NDT should be extended to all areas of the same weld length.

Same weld length mean the locations where, for manual and semi-automatic welding, identi- cal person, identical postures and identical time and, for automatic welding, identical weld- ing method, and identical time.

(C) The extent of testing can be extended at the surveyor's discretion when repeated non- acceptable discontinuities are found.

(D) The Shipbuilder should take appropriate actions to monitor and improve the quality of welds

to the required level. The repair rate at which corrective action is to be instigated should be identified in the builder’'s QA system.

![]()

88 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

(5) Survey records

(A) The survey results are to be recorded to the survey records such as followings and their re- cords are to be filed to compare the inspection locations with their results.

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

(j)

(k)

(l)

Radiation source, type and focal spot size

Geometry of radiographic setup Film type

Intensifying screens Film coverage

Image quality indicators

Film identification marking Exposure conditions

Film processing

Film density

Film viewing conditions

The result of judgement for acceptance

(m) Name of personnel performed the radiographic inspection

(n) Name of personnel performed the radiographic review

(B) The Society may require to duplicate some radiographs in order that some processed films

are handed over to the Society together with testing reports. Alternative method to duplicate the processed film can be agreed with the Society.

4. Ultrasonic Inspection

(1) Methods of ultrasonic inspection

(A) General

(a) The inspection methods other than those specified in this Guidance are to comply with

K S B 0896 (Method for ultrasonic examination for welds of ferritic steel) except in those cases where alternative criteria have been otherwise approved or specified.

(b)

(c)

(d)

In general, the scanning of weld is performed by using angle beam technique. However, normal beam technique is appled to the place where the application of angle beam tech- nique is difficult or the place specially specified as that where the other technique are more suitable than angle beam technique for detecting a discontinuity.

The stage of the test is the time when the final heat treatment is completed, in the case

where heat treatment or the like after completion of weld has been specified in the document.

The test of parent materials of the part through which ultrasonic waves pass when angle

(e)

(f)

beam technique is performed, are previously tested normal continuity such as lamination etc.

The probes may be affixed to suitable wedges designed to

material under test at the selected angles.

The couplant, in general, is to be used the glycerine-water

technique to detect a dis- induce beam waves in the

solution of 75 % or more.

(g)

The kinds and temperature of the couplant used for test are to be equivalent to those used for calibration of ultrasonic test instrument.

The weld reinforcement is adequately finished in case where its form affects the results of the test.

(B) Checking the overall performance characteristics of ultrasonic equipment

(a) The vertical linearity is to be checked in accordance with the 4.1 of the K S B 0534

(Method for Assessing the Overall Performance Characteristics of Ultrasonic pulse echo instrument) and the result is to be within ±3% of full scale.

(b)

(c)

(d)

The linearity of the time base is to be measured in accordance with the 4.2 of the K S B 0534 and the result is to be within ±1% of full scale.

A margin of gain control is to be measured in accordance with the 4.3 of the K S B

0534 and the result is to be not less than 40dB.

Periodical checks of ultrasonic test instrument are to be performed not less once every year. However, The check of the test instrument immediately is to be performed in the case that the repair relating to the performance characteristics of the ultrasonic test in- strument was performed within this period.

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 89

![]()

(C) Probes

(a) In general, the scanning of weld is performed by using probes of angle beam technique.

In case where normal probe is used, the standard is to comply with the K S B 0896.

(b) The frequency to be used for angle beam technique is in accordance with Table 10.

However, the frequency lower than the value specified in Table 10 may be used for the test of test object with remarkable ultrasonic attenuation and the frequency higher than the value specified in Table 10 may be used for improving the resolution.

![]()

Table 10 Nominal Frequency to be used for Angle Beam Technique

Plate thickness of parent materials (mm) | Nominal frequency ( ) |

75 or less | 5 or 2 |

over 75 | 2 |

(c) The refraction angle of probe to be used is to comply with Table 11 according to the thickness of parent materials. Where deemed appropriate by the Society, the different re- fraction angle of probe may be used.

Table 11 Nominal Refraction Angle of Probe used

Plate thickness of parent materials (mm) | Nominal refraction angle |

40 or less | 70° |

Over 40 to 60 incl. | 70° or 60° |

Over 60 | 70° and 45° or 60° and 45° |

(D) Adjustment of ultrasonic test instrument

(a) Measurement of probe index

The probe index is measured by using A1 calibration block or A3 calibration block

specified in K S B 0831. The probe index is measured in precision of ±1% and to be indicated on the both sides of probe.

(b) Measurement of refraction angle

Refraction angle is measured in unit of 0.5° by using A1 calibration block or A3 cali- bration block

(c) Adjustment of time base range and correction of the starting point

The adjustment of time base range is performed in precision of ±1% by using A1 cali- bration block or A3 calibration block and the starting point is corrected.

(d) The equipment (instrument and probes) should be verified by the use of appropriate standard calibration blocks at suitable time intervals.

(E) Making of curve for dividing echo height

(a) Curve for dividing echo height

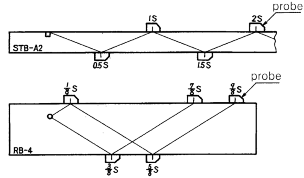

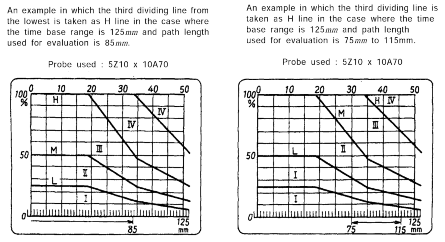

The height for evaluation of the depth is made for four regions specified in Fig 2. The positions of probe for making the curves for dividing echo height using the distance

amplitude characteristic curve are to comply with Fig 1.

(b) Determination of H line, M line and L line

The curve for dividing echo height by working sensitivity of (d) is selected to take it as H line, and the curve for dividing echo height lower than H line by 6 dB is taken

as M line and the curve lower than H line by 12 dB is taken as L line. H line is of

over 40 %.

(c) Regions

The regions divided by H, M and L line are designated as given in Table 12 and the

examples of regional division are indicated as given in Fig 2.

![]()

90 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Fig 1 Position of Probe for making the Curves for Dividing Echo Height

Fig 2 Examples for Drawing Curves for Dividing Echo Height

Table 12 Designation of Regional Division of Echo Height

Range of echo height | Region of echo height |

L line or less | I |

Over L to M line incl. | II |

Over M to H line incl. | III |

Over H line | IV |

(F) Working sensitivity

(a) Using the A2 calibration block

In the case of using nominal refraction angle of 60° or 70°, the gain of instrument is adjusted so that the echo height of the standard hole of ![]() 4 x 4 mm agrees with H line. In the case of using nominal refraction angle of 45°, the gain of instrument is

4 x 4 mm agrees with H line. In the case of using nominal refraction angle of 45°, the gain of instrument is

![]()

in- creased by 6 dB after it is adjusted so that the echo height of the standard hole of 4 x 4 mm agrees with H line. In both case, where deemed appropriate by Society,

sensi- tivity compensation calculated according to Annex of K S B 0896 to be added.

(b)

Using the RB-4 reference block

The gain of instrument is adjusted so that the echo height of the standard hole agrees with H line.

(c) Where deemed appropriate by the Society, other blocks considered as equivalent block specified in (a) and (b) may be used.

for

(d)

The range and sensitivity should be set prior to each testing and checked at regular

tervals as per the procedure and whenever needed.

in-

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 91

![]()

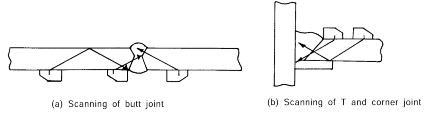

(G) Position and direction of scanning

(a) In general, the scanning of weld is performed by using angle beam technique and scan- ning method is comply with the Table 13 and Fig 3 depending on the type of joints

and plate thickness. However, for welds in which the surfaces have been ground, the

probe is placed on the weld surface and moved along the

beam directed parallel to the weld.

weld axis with the sound

![]()

Table 13 Position and direction of scanning

Type of Joints | Plate thickness (mm) | Position and direction of scanning | Scanning | methods | ||||

butt joints | t 100 | both side of single face | Directed and 1 | skip reflected. | ||||

t > 100 | both side of both face | Directed | ||||||

T joints, corner joints | t | 60 | single side of single face | Directed | and | 1 | skip | reflected. |

t > 60 | single side of both face | Directed | ||||||

![]()

Fig 3 Position and Direction of Scanning

(b) The scanning technique should be determined to allow the testing of the entire volume of the weld bead and base metal for at least 10 mm on each side of the weld, or the width of the heat affected zone, whichever is greater.

(H) Ultrasonic discontinuity length and presentation of location of discontinuity

(a) Ultrasonic discontinuity length

(i) The position indicating the maximum echo height is taken as center of scanning, the

transference distance of the probe in the range where the echo height exceeds L line is measured by scanning its circumference is taken as the ultrasonic discontinuity length. The measurement is performed by unit of 1 mm.

![]()

(ii) In the case where the plate thickness of part where the probe is contacted is not less than 75 mm, nominal frequency is 2 and the probe with transducer size of

20 x 20 mm is used, the transference distance of the probe in the range where the echo height exceeds one half of the height of the maximum echo is taken as the ultrasonic discontinuity length.

(b)

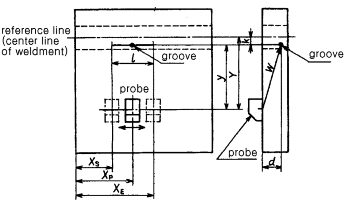

Presentation of location of discontinuity

The discontinuity location in the transverse section [depth(d) and distance(k) from weld

centerline] is presented by the probe location(Xp) where the maximum echo can obtain. The discontinuity location in the plane is presented by both ends((Xs and Xe) of ultra- sonic discontinuity length(l)

![]()

92 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Fig 4 Presentation of location of discontinuity

(2) Extent of survey

(A) Survey of welded joints of the shell and deck plating in ships

(a) The survey location and distribution of checkpoints of ultrasonic ply with the requirements given in (A) of 3 (2).

inspection are to com-

(b) Test range of ultrasonic inspection is entire length of the joint or 750 mm, whichever is smaller.

(B) Survey of welded joints of internal structural members of ships

(a) The survey location and distribution of checkpoints of ultrasonic inspection are to com- ply with the requirements given in (B) of 3 (2).

(b) Test range of ultrasonic inspection is entire length of the joint or 300 mm, whichever is

smaller.

(C) Workmanship control of welded joints of hull

(a) The survey location and distribution of checkpoints of ultrasonic inspection for work- manship control of welded joints of hull are to comply with the requirements given in

(C) of 3 (2).

(b) Test range of ultrasonic inspection is to comply with the requirements given in (B)

above.

(D) Addition/Reduction in the number of checkpoints

Addition/reduction in the number of checkpoints is to comply with the requirements given in (D) of 3 (2).

(3) Acceptance Criteria of ultrasonic inspections

(A) Defects detected by ultrasonic inspection are to be judged in accordance with Table 14

![]()

![]()

Table 14 Acceptance criteria for defects detected by ultrasonic inspection

Thickness of base metal t (mm) | t 50 | 50 < t | t 50 | 50 < t | |

Region of maximum echo heights | II and III | IV | |||

Acceptance Criteria | length of defect (mm) | t or less | 50 or less | t/2 or less | 25 or less |

Note: 1. (1) The symbol t is plate thickness (mm) of the parents materials of the groove side. However, in the case of butt joint weld with different plate thickness of the parents materials, the thinner plate thickness is adopted. 2. In applying this table, in the case where the distance between discontinuities is smaller or equal to the length of the discontinuity with longer ultrasonic discontinuity length that the depth considered to be same, these discontinuities are regarded as same discontinuity group and treated as a continuous dis- continuity including such distance. In the case where the distance between discontinuities is longer than the larger one out of the both ultrasonic discontinuity lengths, these discontinuities are regarded as in- dependent from each other. The examination results of straddle scanning, parallel scanning by slanted probe and longitudinal scanning on the weld line are classified in accordance with the agreement be- tween the parties concerned. | |||||

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 93

![]()

(B) Where kind of defect is considered as cracks from welding process, location of defects, the defects are to be judged unacceptable.

(4) Repair and Treatment after the Repair

Repair and treatment after the repair is to comply with the requirements given in 3 (4).

(5) Records

(A) Making the records

The records after test are to be made.

(B) Items of Records

The records are to be included the followings.

(a) Name of the work and manufacturer

(b) Number and name of ship

(c) Name and qualification of personnel engaged in the test

(d) Date of the test

(e) Calibration and reference blocks used

etc.,

(f)

Performance of test instrument (identity, probe type, size, frequency, angle etc)

(g) Unusual condition of weld bead

(h) Method of welding and form of groove

(i)

(j)

Materials and dimension

Location and length of the welds inspected

(k) Length and location of discontinuity

(l)

Classification

(m) Kind of couplant

(n) Working sensitivity

(o) Other items(designated items, subject of discussion, witness, sampling method etc.)

(C) Evaluation of records

The ultrasonic test reports is to be made under condition of rigid quality control and be to the satisfaction of the Surveyor.

5. Improvement of qualification

Where the faulty welds are more than 10 % of the number of inspection specified in Table

is to

4 or

5, the results of investigation on the substantial cause and the measures to improve the quality are

to be submitted to the Surveyor. ![]()

![]()

94 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()